In an effort to make some headway, I decided to get this beast running before committing to anything cosmetic. That has been proven a bit troublesome so far.

I have been searching for a washer that goes on the points cam shaft, but the part is no longer made. Used was the only option, and there just weren't any floating around, or so I thought. After draining the oil and checking the sump screen I found the washer needed sitting inside the clutch cover! That's some good news.

While waiting on a new oil filter to come in, I decided to see what it would take to replace the shift shaft. Some dingleberry welded the lever to the shaft after stripping it out. In order to replace the whole shaft, I had to cut off the lever and grind it smooth enough to fit through the seal.

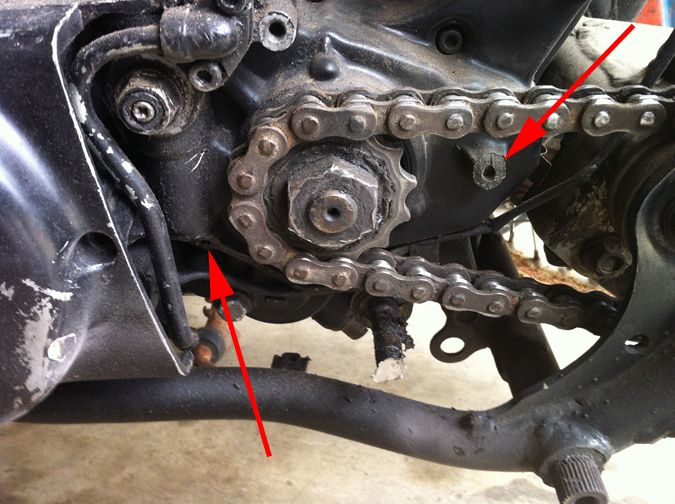

Then I noticed some broken bosses on that case side that normally are used to hold the sprocket cover on. Guess it's time to make a case saver off what little mounts I have left.

Moving on, I had to remove the clutch basket to get to the shifter pawl and slide it out. After removing all the springs and plates I went to remove the nut holding the basket on. Loose as a goose, absolutely no resistance whatsoever. Definitely glad I decided to replace the shaft now instead of down the road, cause finger tight wouldn't have done me any good.

I'm sure it was mentioned previously, but my kicker idler gear is missing a tooth, and in my cheapness I originally wanted to just leave it be. I've since decided to replace it and save myself any more future drama considering all the other stuff popping up.

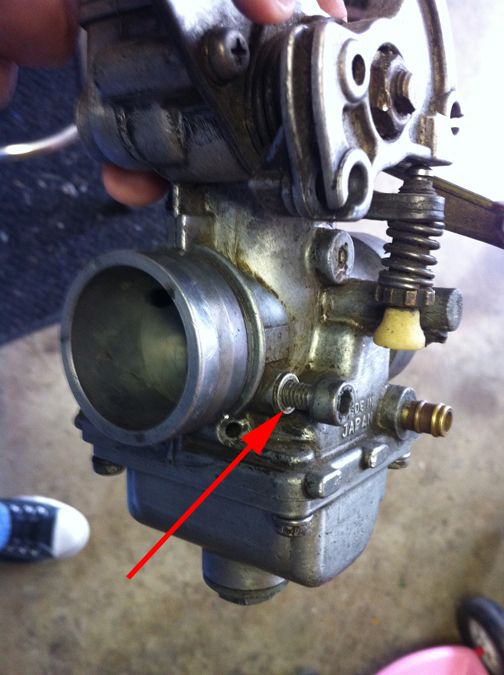

I found a shift shaft, kicker idler gear, and some various hardware for a real good deal on eBay. Just need to order a new shaft seal and boot to finish it all up. In the meantime I decided to dig into the carb and see what awaits. Luckily someone has done all the cleaning for me, but put an extremely long screw in what is only described as a plug in the parts catalogs. I'll get a new one ordered up and start fiddling with some wiring.

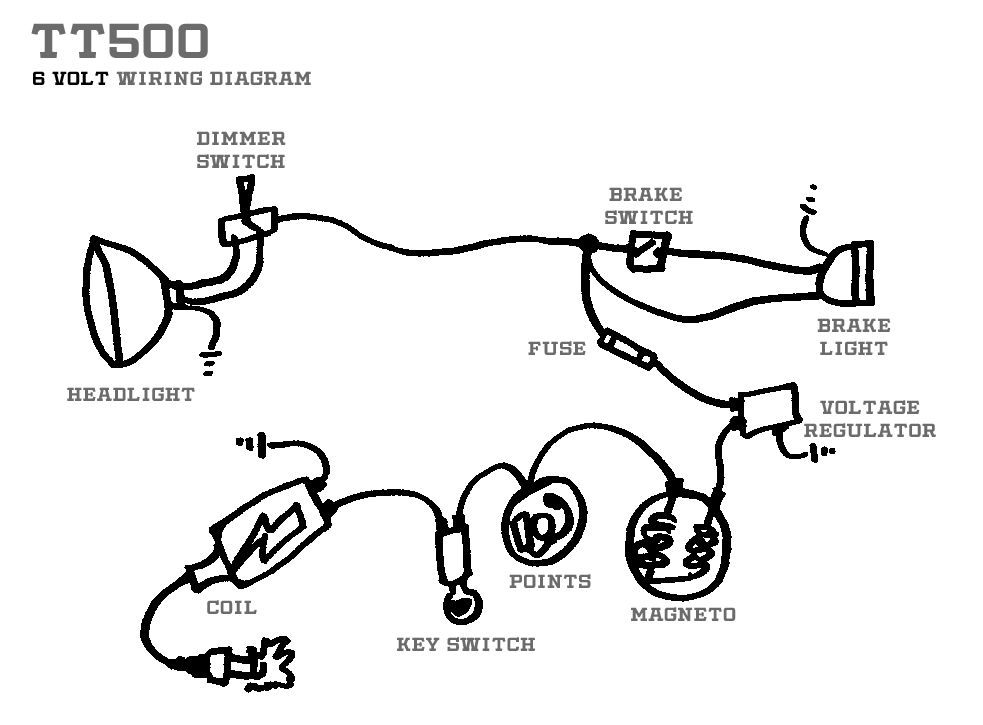

The 6v system that came stock on the tt500 has an unused lighting coil in stock trim. Simply wire up a voltage regulator and I'll have a magneto fed light system requiring no battery! Here's what the stock wiring diagram consists of.

I'll replace the kill switch with a keyed one, add in a 6v voltage regulator, a fused lead for lights, and brake light switch.

Derrick

10/1/12

tt500 build : part 2

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment