We have been pecking away at the tasks to get this Ozark Mountain Scramble Ironhead ready for June 2014. Here in Western New York the riding season stops at the end of October so shop time is not interrupted by the desire to ride in sub-freezing temps until April.

The Rear spring struts were not doing it for me for the overall look of this bike. The rear sat too low and the front is too high. I found a pair of stock 13-3/8” long XL883 rear shocks in my stash that I removed from my wife’s new Sporty back in 1997. These brand new shocks have been in a box in my attic for the last 16 years. I figured this project was the perfect candidate to use these forgotten gems. So, off with the struts and on with the shocks. I like the look better than the struts on this bike but they are really soft and with my fat ass on the bike the springs compress farther than I would like. I guess we will be adding pre-load spacers to the springs to carry the extra load and keep the sag to a manageable level. We will post more on that procedure in the future.

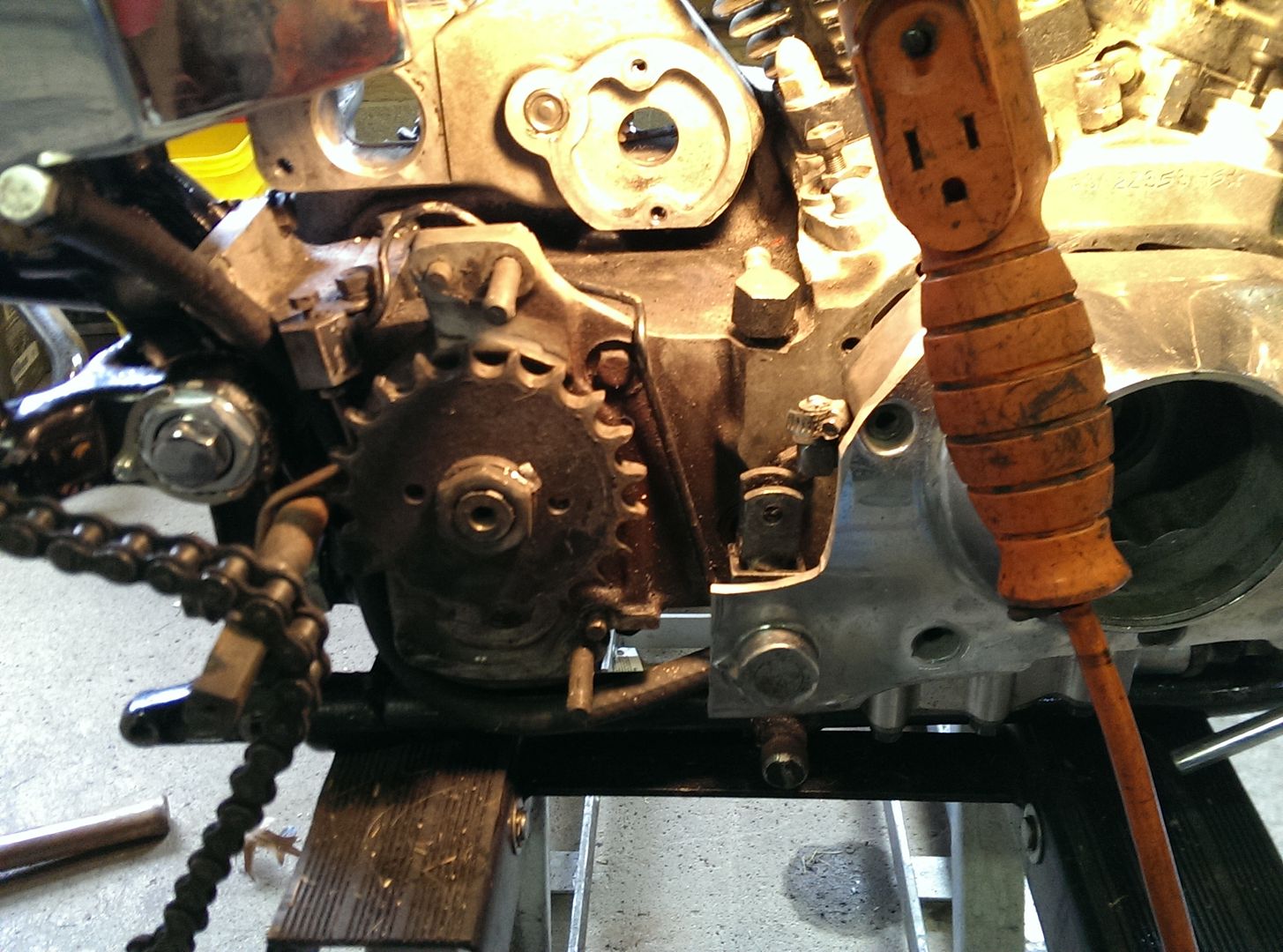

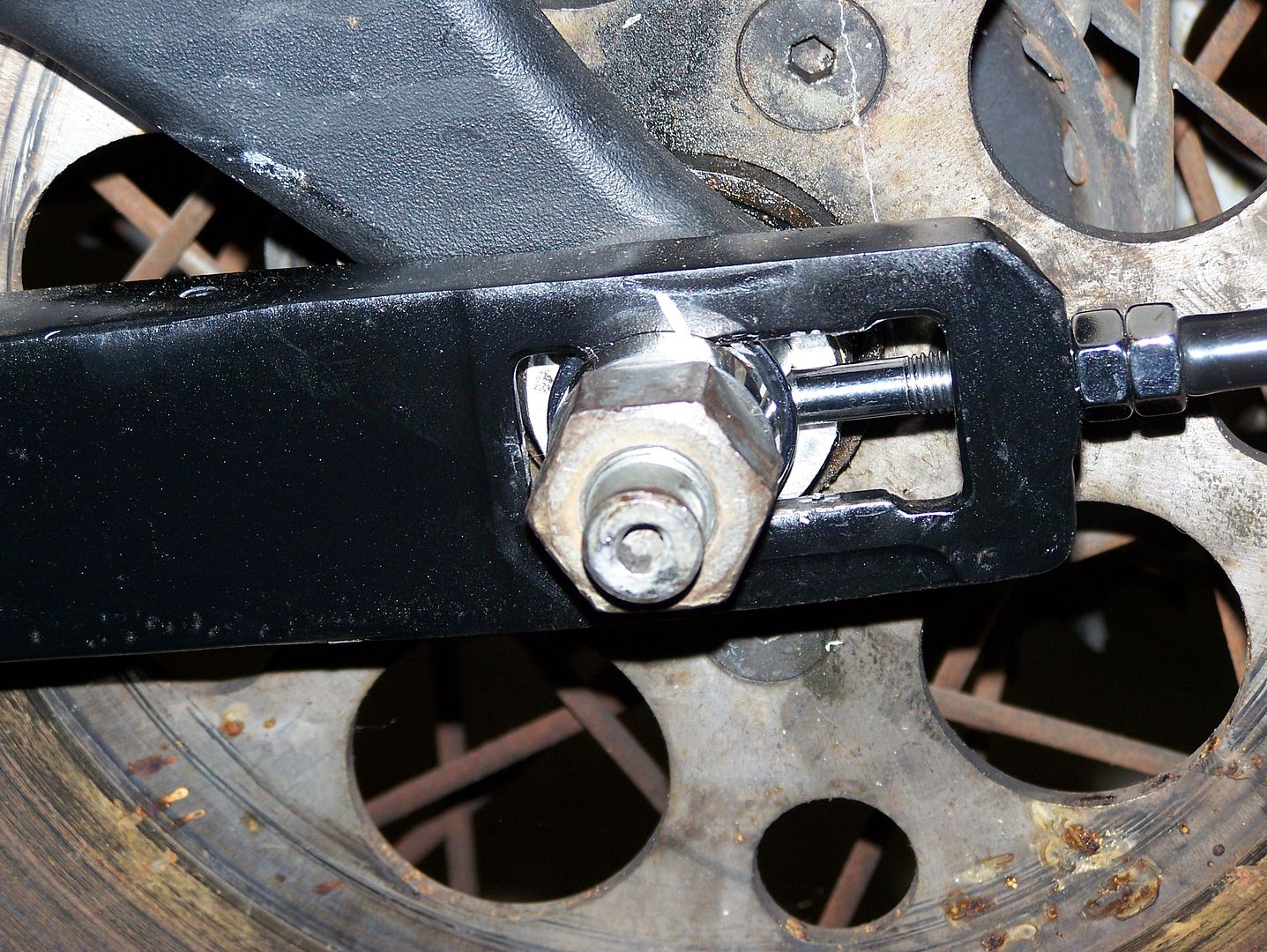

The Ironhead motor will be losing half of its displacement when I remove the rear cylinder so we needed to give the motor a little help in the final gearing department. We installed a smaller countershaft sprocket for some extra mechanical leverage. We went from and 23/49 combination to a 19/49 combination. I pulled a few links form the existing chain so everything fits correctly. I hope this is enough to let this bike get out of its own way on the twisty mountain roads of Arkansas.

We decided to use the horseshoe style oil tank that came in the box of parts with the bike to keep costs down and mounting of the battery simple. The only problem is the original tank mounting system is flawed and parts are missing. I rigged the tank to mount from the original regulator/battery box iso mounts and reworked the original oil tank frame mount on the right side of the bike to hold that side and the third mount will have a custom bracket that ties the oil tank to the inner primary. I am hoping the iso mounts and the 4 point mounting configuration will be enough to hold the weight of the battery and 3 quarts of oil. This is all for now stay tuned for the next update for the rear tail section and foot controls.

Tim

12/30/13

OMS Ironhead Thumper : 04

12/13/13

tt500 build : part 11

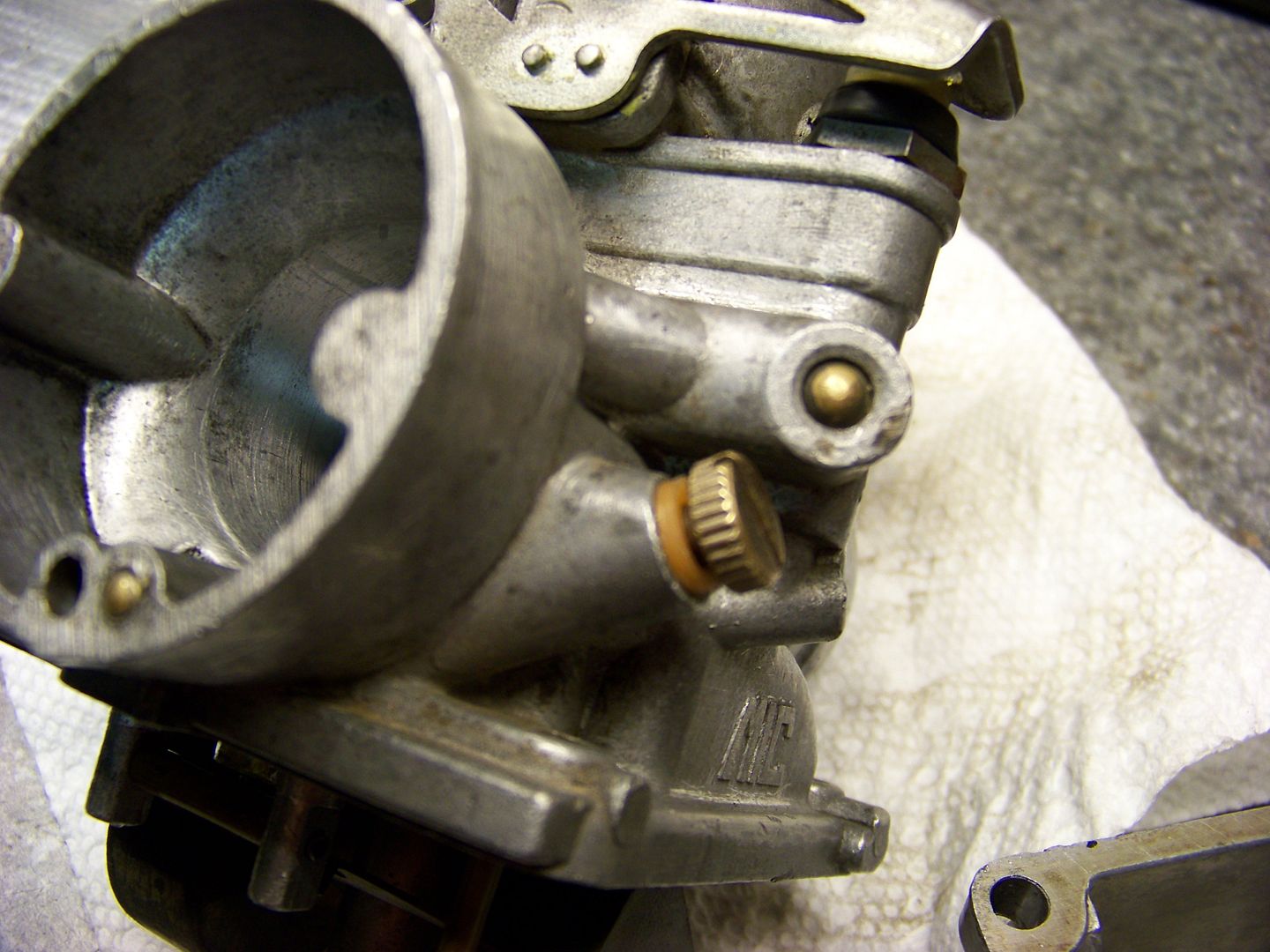

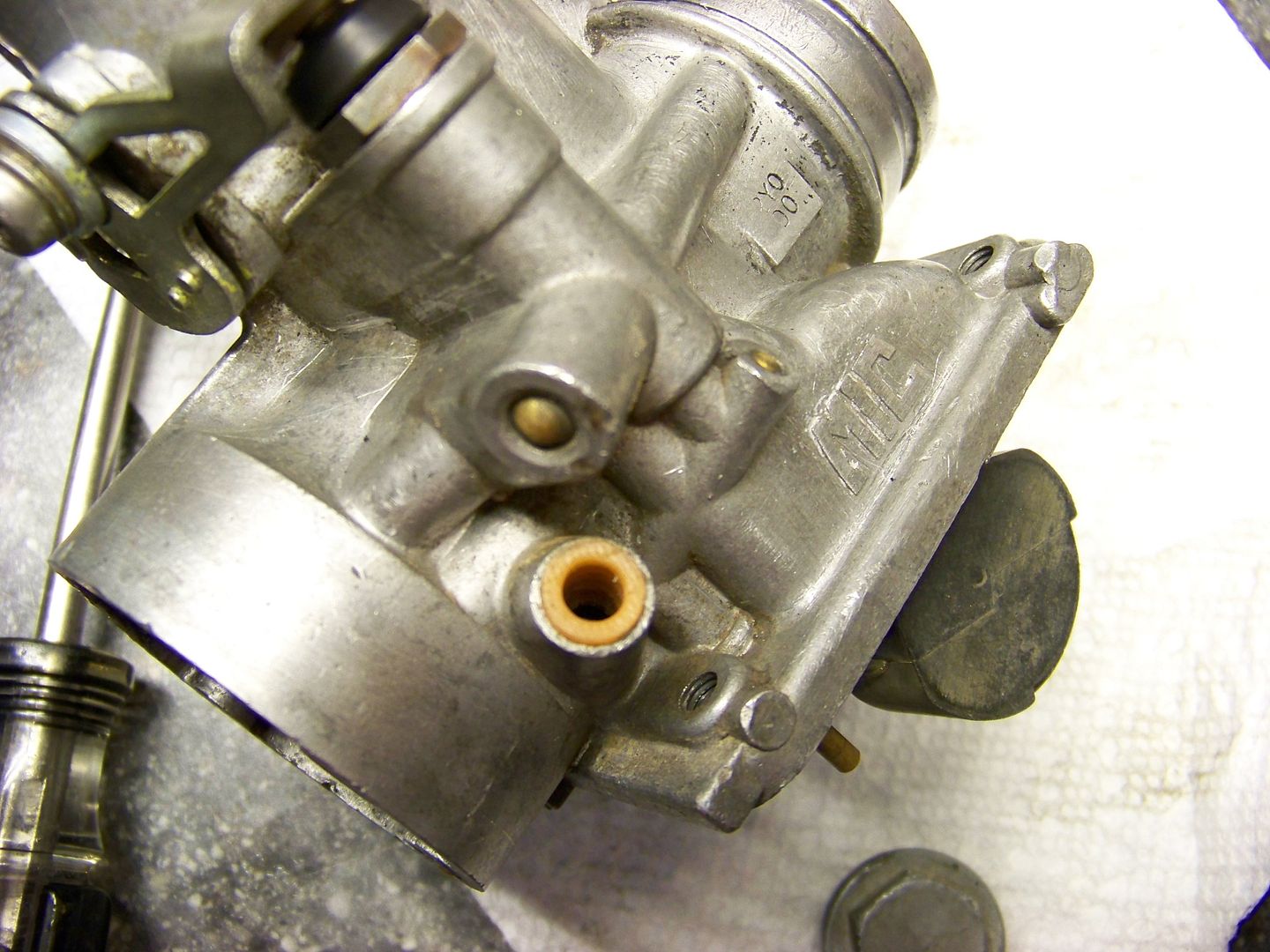

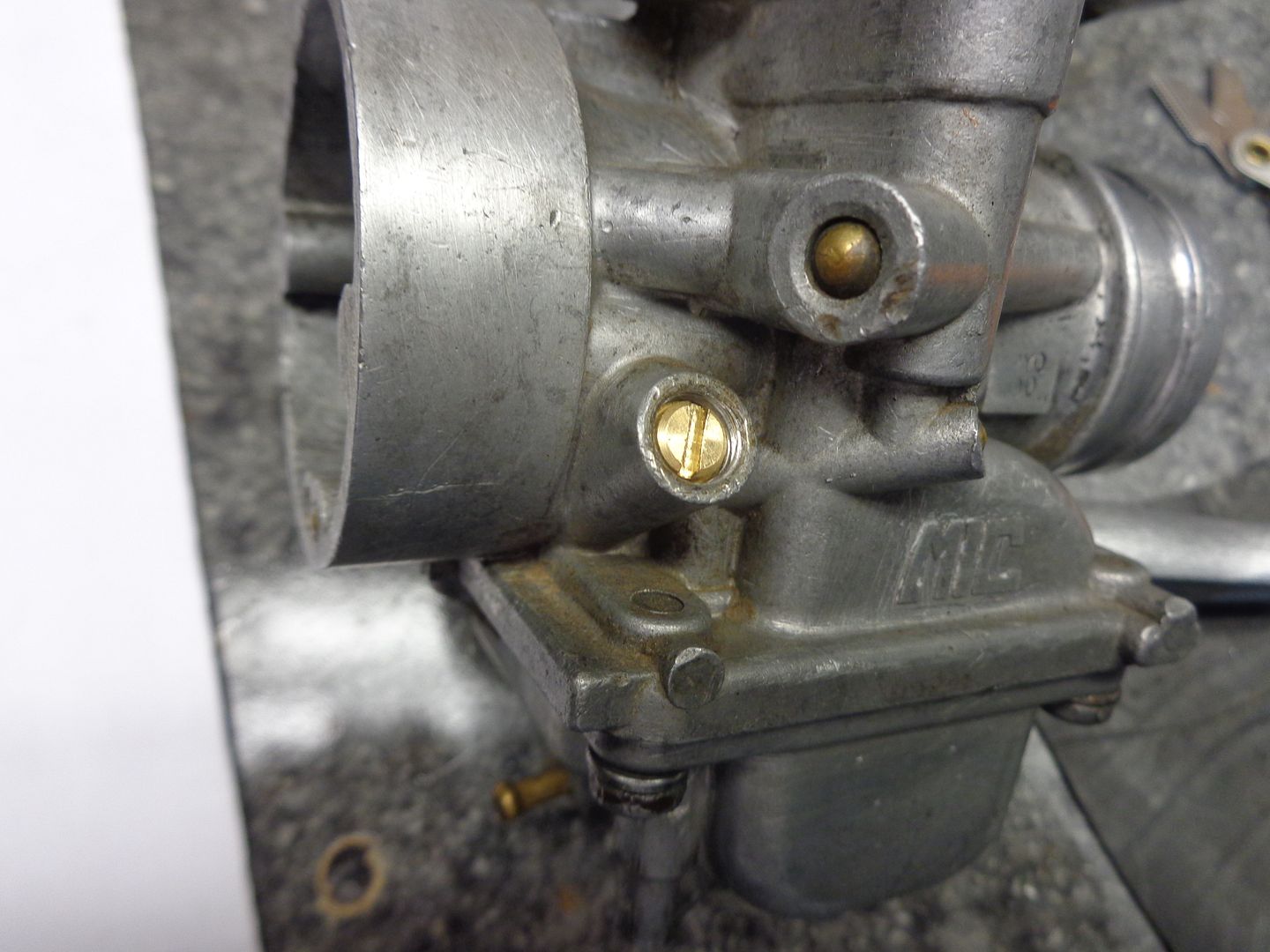

When I got this bike running, it was clear the carb was having idle issues. This mixture screw was probably the main reason why. Stupid screw. I have no clue what bike it came off of, but it isn't the stock one.

Then there is this plastic liner thing. It almost looks stock right?

Nope. That is a drywall screw anchor thingy. I don't know the technical name, but that's what it is.

The threads in the carb body were a bit galled, so I chased them with a tap and put the new mixture screw kit in. If this doesn't fix the problem, I'm going to push the bike in a lake. Maybe. I'm sure the wheel bearings will lock up when I try to move it into the murky water.

Now on to the front brakes. In a search for simplicity, I decided to find a bolt on caliper for the tx750 forks. Apparently the body for these were used for a handful of different Yamaha bikes of the era. From the xs650 to the rd350, the bodies are the same, and with a quick hardware swap can be moved from one side to the other depending on application. On top of that, the rear calipers on some models were the same.Yay?

Unfortunately the front calipers usually run a flared fitting with a short hard line, while the rears run banjo. I don't want the extra connections, and prefer just a more common banjo fitting with a single line. A little light reading told me that the flare fitting will pop out after threading a screw through it. Sounds simple enough.

With a gentle tug, it popped right out. Ready for banjo duty.

Since this project seems to be a never ending car crash, it's fitting to find out my current xs650 rotor is the wrong one. The offset on the later model bikes were different than the early ones. The early 2 piece will fit my setup, but the one piece won't. Dammit. That's where I'm stuck. If anyone out there has one they will let go of, shoot an email to hatchethairy@yahoo.com and hopefully we can work out a deal. It looks like this.

11/25/13

OMS cl350 : 02

I have fixed the exhaust, put a new battery in it and cleaned the carbs got it running

pretty sweet now.

I also put the stock fenders back on it front one had to raise a little cause of the tire sizes.

The rear one came with a Lucas style tail light and a stock style tail light.

I picked the Lucas style after careful consideration..lol it's a smaller light that looks way

better than stock in my opinion.

Now I got the fenders on and tail light working I can got register it and be legal like on the

roads and such.

Time to get rid of this seat and get a stock seat and possibly put the scrambler bars on.

I'm liking the ones on it now damn decisions.

That's it for now.

Happy Thanksgiving to you all!!

Dean

11/21/13

OMS Ironhead Thumper : 03

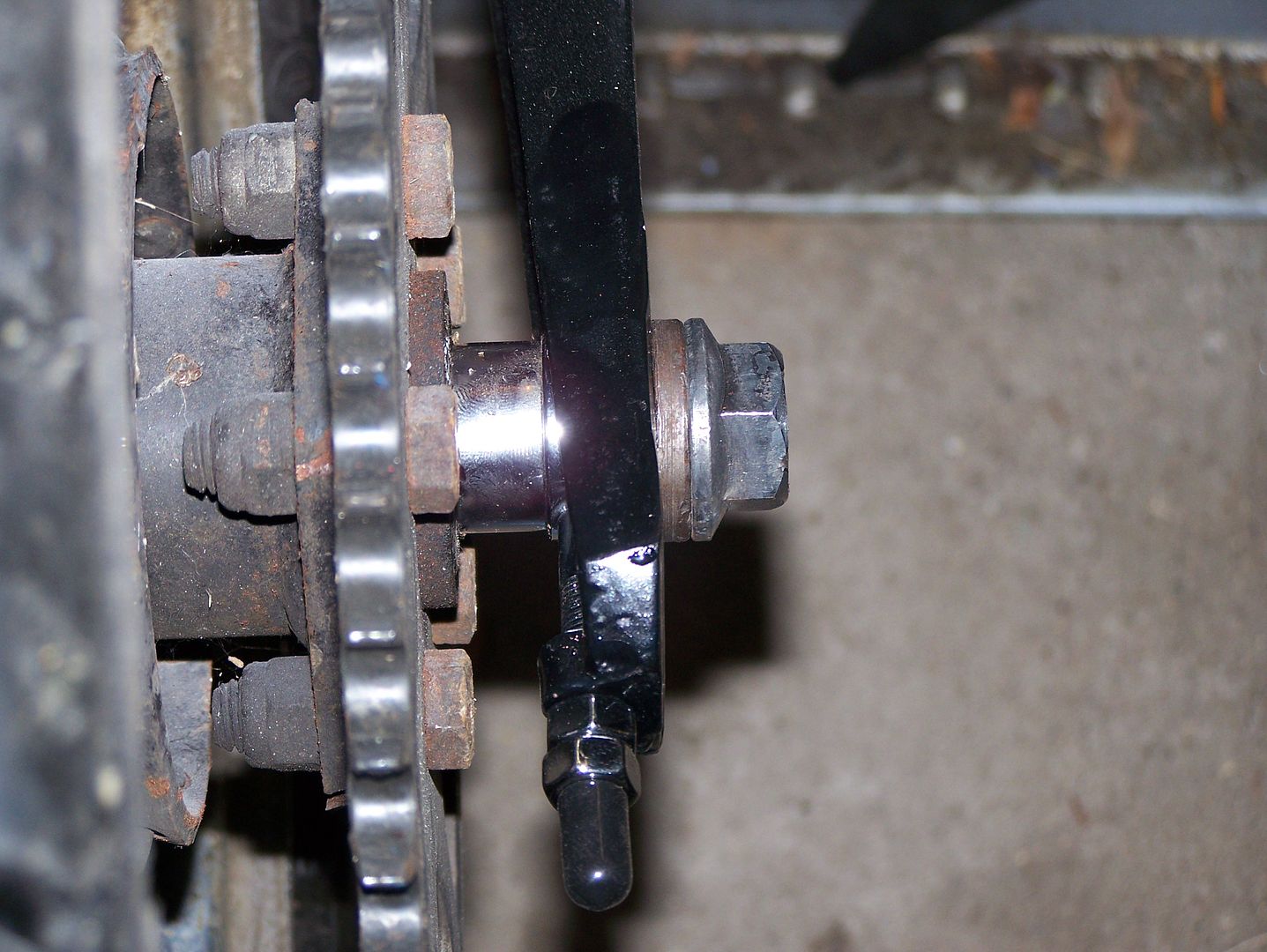

This project has been sitting for a month or so. I figured it was time to move forward and get the rear wheel mocked up and on the bike. That one sentence took a week of after work free time to get completed. First of all the wheel that we had acquired with the project is a later disc brake wheel. In 1975 the Sportster came with a Drum brake rear wheel. I thought to myself “No big deal we have a caliper and a master cylinder to use for this.” So I went to bolt the whole assembly up and what I realized is the later disc brake wheels use 3/4” Id bearings and the original drum brake set up used 5/8 ID bearings. All the original hardware was useless as is. What to do? I found a 3/4” diameter axle and nut in a box of parts but it was 2-1/2” too long. I cut the head off the original axle and drilled a 1/2” diameter hole through the center of the head and cut the 2-1/2” inches off and turned a 1/2” post on the axle then proceeded to weld the head back on. Next on the hit list was the axle adjusters needed to be opened up to 3/4” also. I went back to the lathe with a boring bar to make short work of this task. The 3/4” axle needs to ride in a 7/8” slot in the swing arm so 2 spacers with 7/8” flats were made to center the axle in the slots in the swingarm. The last piece of this puzzle was a 3/4 long straight spacer. I found a chrome one in a box from a previous build. All of our work bolted right up and lined up the wheel and sprocket like it was meant to be there. Next on the list is to fabricate an anchor for the brake caliper to the swingarm.

We mocked up and installed the fuel tank. The tank it is one of the few new parts of this build so far. With the tank bolted on the coil and bracket was located and installed as well as the front and rear head with the rocker boxes. This is all temporary until we get the body fab work completed then the motor will come out for the cylinder modifications.

Tim

11/15/13

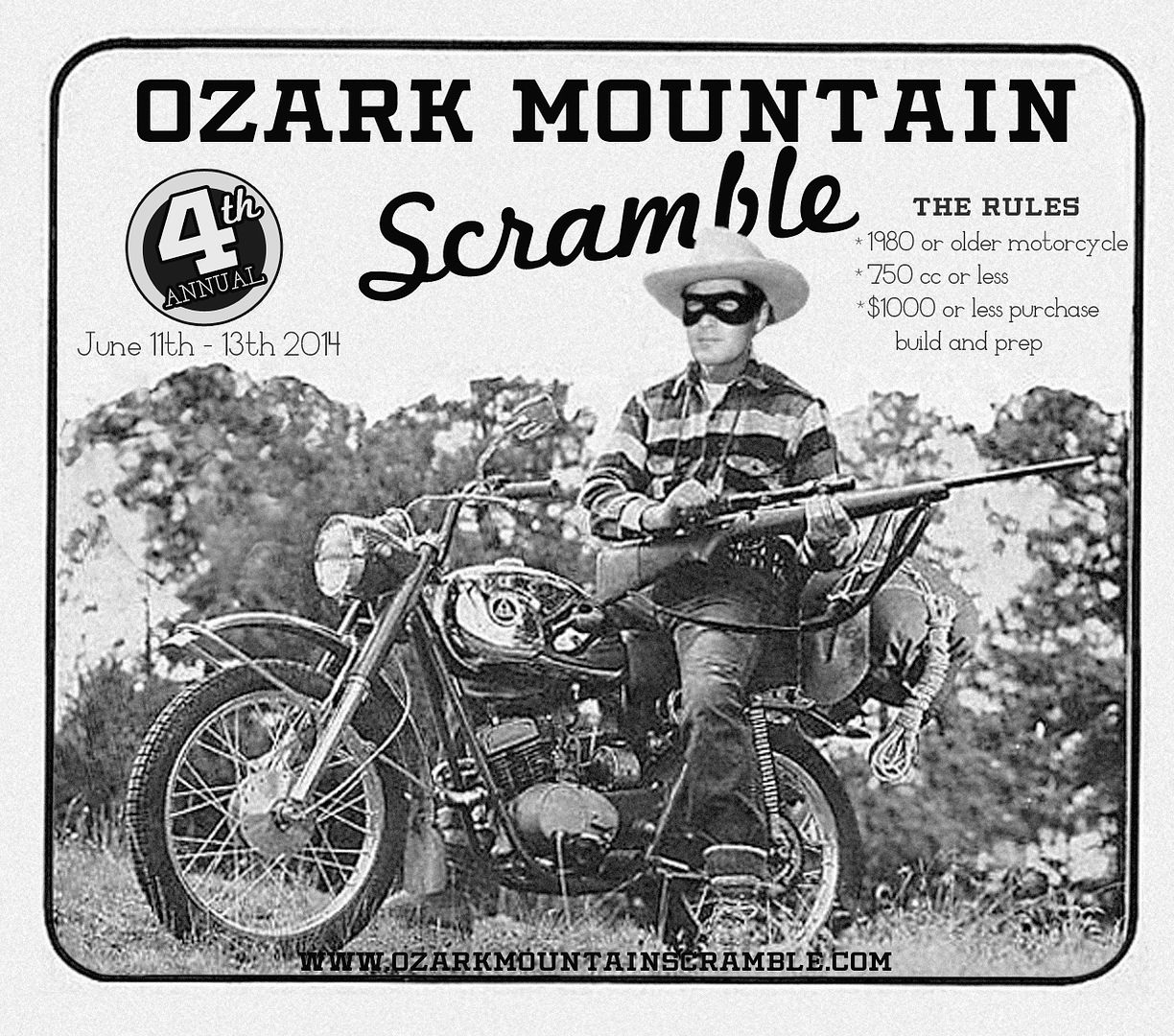

ozark mountain scramble 2014

Just a quick reminder to get out there and find a cheap bike for June. It really is the most fun per dollar you can squeeze out of a motorcycle ride. Period. The Ozark Mountains provide some of the best riding in the country, and that's putting it lightly. This isn't a show. There won't be any trophy's. Just good old fashioned fun. Wanna know more? Go to www.ozarkmountainscramble.com to get all the information you should need to join.

Here's some of the rider submissions so far, and it's only November:

Andy's cl360

BG Uno's Moto Guzzi

Tim Statt's Thumper Ironhead

Dean's cl350

Derrick's kz440

11/7/13

OMS cl350 : 01

Hi, my name is Dean and my good friend Tim turned me on to this adventure and got me interested to go.

So I picked up this 1972 CL350 Scrambler locally for 800.00 and so far bought a 60.00 battery.

I will be attending the Scramble with this bike.

I have to clean the carbs and change the oil as the bike has been sitting for quite a spell.

The bike did come with the original front and rear fenders and taillight and some misc. parts.

I also have a 1970 sl350 but that bike is seized and I wont be bringing it to the scramble

but I might need some parts of it to stay within budget.

I will have some better pics shortly as I put the fenders and taillight back on and other things

I am doing to the bike to get it ready......

Dean

10/22/13

OMS Ironhead Thumper : 02

Have you ever put together a 3 dimensional puzzle? Well this is what we have here. My plan at this point for the “Half A Harley” is to assemble everything as intended from the factory, then do the fab work for the custom bits and finally pull the motor and make it from a v-twin to a thumper single.

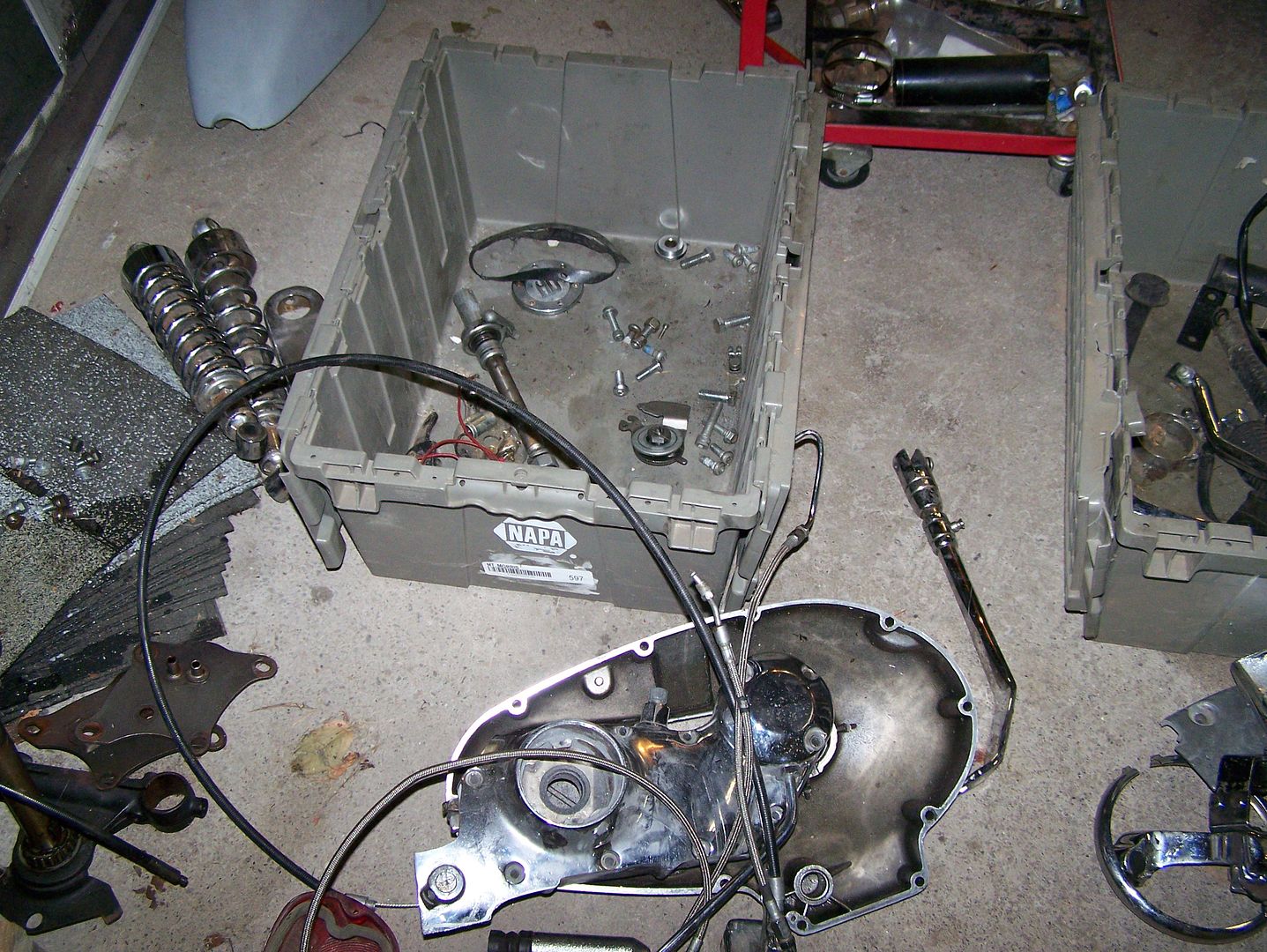

The bike arrived at my shop in a few totes. I separated out what I know fits and where it goes. As with every puzzle you need to start somewhere. I start with first the easy large things that I know where they belong and hopefully everything else will fall into place as the boxes get emptier.

One of the biggest hurdles is locating all the fastening hardware as I go. I have a very good selection of used bolts and fasteners from other projects that I have done over the years. I will be mining for the correct hardware in the various boxes and totes that I have acquired. As you may know most shops have a miscellaneous bolt box around to catch all the cast offs when the project is complete.

So far we have rebuilt the swing arm pivot and installed the vintage spring struts out back, then added the dual disc front end taken off my last project. I am saving The Performance Machine calipers and the mounting brackets that were included with this bike for another project or if needed to sell off to keep my budget below the $1000.00 max limit. The motor is installed in the frame and the front brakes are plumbed and bled using a combination of used custom vintage steel braided lines and stock Harley rubber brake lines. It is not the prettiest set up but it is cheap and works.

Next on the list is to get the disc brake rear wheel and caliper mounted up and on location. This bike is supposed to have a mechanical drum rear brake with a 5/8” Axle diameter. I am installing hydraulic disc brakes with a ¾” diameter axle so some machining is in order to get the whole deal to work together.

Tim

10/21/13

OMS kz440 superbike : 10

Need to up the secondary mains a bit, figure out a seat, and some other gibberish. Just about road legal to start raping the streets.

Derrick

10/16/13

OMS kz440 superbike : 09

Got a lot done in the past month or so. I really wasn't digging the bottom mount Bates style headlight on this bike. It looked out of place, and the bracket I made was just janky. I really liked the stock unit, so I chopped down some old universal brackets to weld onto the fork covers I previously made. Super tight fit, but it looks much better. Added some fork gaiters that still need some trimming, but we are inching closer. Also got in a new master cylinder since the stocker was shot. I saved some much needed cash on the budget by keeping the stock headlight, caliper, and brake line.

Things weren't progressing quick enough for me, so I took a full vacation day off work to get out in the garage and get the 440 going. I did the following:

carb diaphragms

set float height

blow out jets and openings in carbs

install all new carb o-rings

make new pilot screw washers(missing)

install petcock

fuel lines trimmed and quick disconnect on tank for fuel crossover

oil uni-filters

handlebars trimmed

handlebar grips trimmed

front brake bled

throttle assembly setup/adjusting

throttle cable routing/adjusting

clutch cable routing/adjusting

wire/install new coil/plug caps

install new regulator rectifier

install chain/adjust tension

adjust and clearance rear brake pedal/linkage

finish wiring everything but the lights

adjust points/timing

fork fluid

tighten up exhaust

I didn't think to have a battery fully charged and ready to go, so instead of hearing a beautiful roar, I got to hear the starter chug a couple times and that was it. After some trickle charging, I finally got to hear it run. Shitty. I spent about a week chasing down little issues here and there. Once I got it to idle, mid throttle it would just cackle an cut out instead of rev. Found out the points/condenser were trashed, and now it revs to the moon with ease. I have a slight, and I do mean slight, hesitation at idle. Here's a video of one of the first rides when the points were bad.

Still tuning for the most part, but now I can focus on making a seat pan, inner rear fender, chain guard, front fender, and sealing some oil leaks on the side covers.

Derrick

10/8/13

OMS Ironhead Thumper : 01

So I decided to throw my hat in to the ring for another Ozark Mountain Scramble. I deal in American bikes and parts on a daily basis so I thought it would be a good idea to utilize my knowledge or interchangeability and a part stash from other projects that I have done.

We will be building a 1975 Harley Davidson Sportster. You say foul! Harleys cost too much and are too large for the displacement rule! As you may know the Ironhead Sportster is at the bottom of the food chain as far as American V-twins are concerned. They can be acquired for a song running and if you do a little wheeling and dealing you can get a basket case bike on the cheap.

Have you ever heard the term for a Sportster as “Half A Harley”? Well that is what we plan on doing to get the bike to fit the 750cc displacement rule. The 1975 Ironhead Sportster motor is a unitized construction V-Twin with cast Iron cylinders and cast Iron heads hence the term “Ironhead”. We thought that we would cut down on the bore by sleeving the cylinders and new pistons. This would make it a 750cc V-twin. The more I thought about it nobody would believe me that I really did the work as there would not be a good way to check the motor to make sure I was not telling a tall tale. So, the plan is to take this V-Twin and turn it into a Thumper Single! I have a few ideas on how to go about this. We will be posting pics as the progress unfolds over the next few months.

Tim